Guide to Vacuum Cleaners to Consider Avoiding in 2026

Introduction to Industrial Dust Vacuums

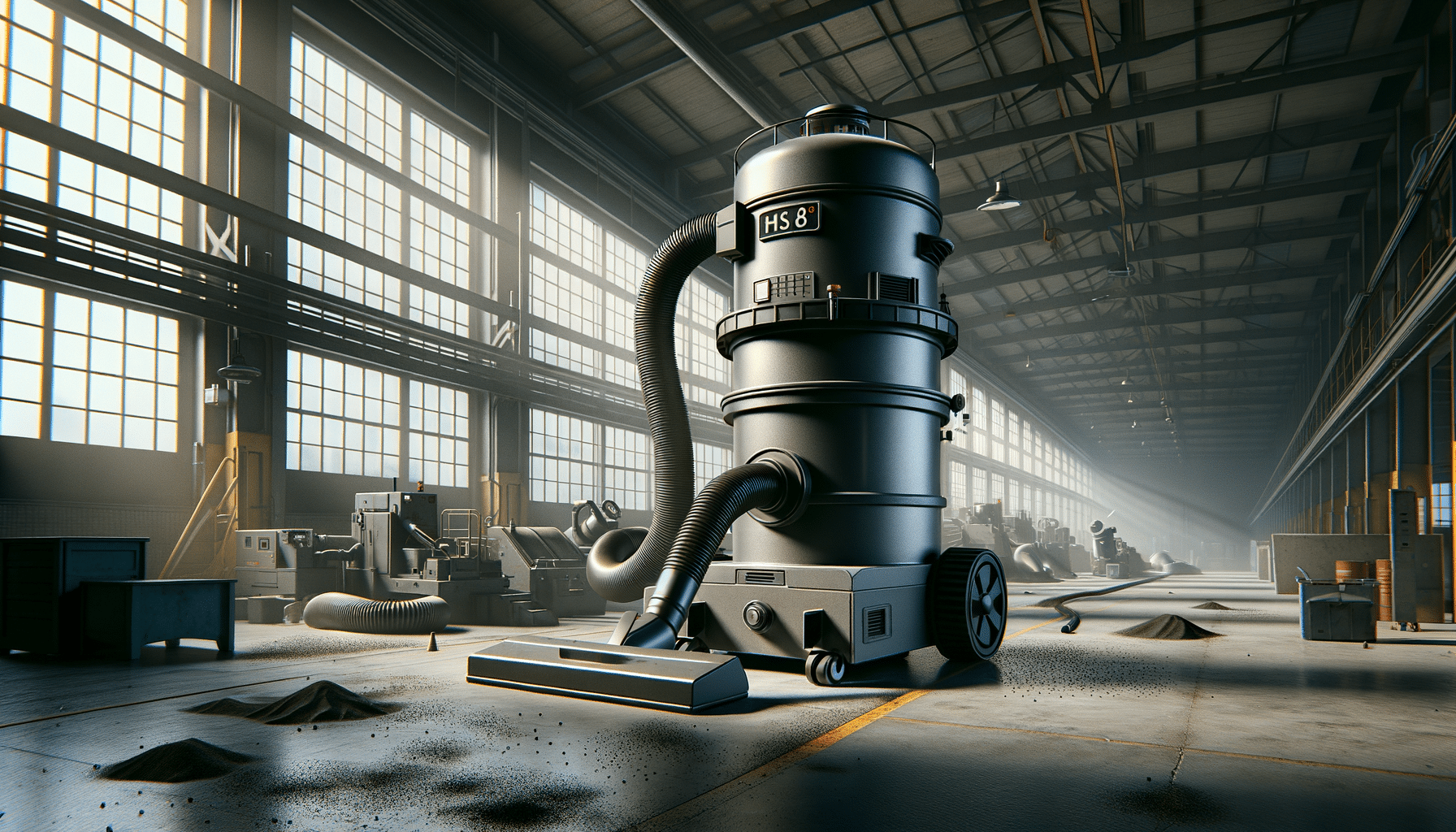

In the world of industrial cleaning, ensuring a clean and safe environment is paramount. Industrial dust vacuums play a crucial role in maintaining cleanliness in various settings, from factories to construction sites. These powerful machines are specifically designed to handle large volumes of dust and debris, making them indispensable in industries where dust accumulation can pose significant health and safety risks. This article delves into the importance of industrial dust vacuums, exploring their features, benefits, and considerations for choosing the right one.

Understanding the Mechanism of Industrial Dust Vacuums

Industrial dust vacuums are engineered to tackle the demanding requirements of industrial environments. Unlike standard household vacuums, these machines are built with robust motors and durable construction to withstand heavy usage. Key features often include high-capacity dust collection systems, advanced filtration technologies, and powerful suction capabilities. One of the standout components is the filtration system, which typically consists of multi-stage filters designed to capture even the finest dust particles. This ensures that the air released back into the environment is clean and free from hazardous contaminants.

Moreover, industrial dust vacuums are equipped with large storage tanks or bags to accommodate substantial amounts of debris, minimizing the need for frequent emptying. Some models also feature self-cleaning mechanisms for the filters, enhancing operational efficiency and reducing maintenance time. The design of these vacuums prioritizes ease of use and safety, with ergonomic handles, sturdy wheels for mobility, and safety features to prevent overheating or electrical faults.

Applications and Benefits of Industrial Dust Vacuums

The versatility of industrial dust vacuums makes them suitable for a wide range of applications across different industries. In manufacturing plants, they help maintain equipment by preventing dust accumulation that can lead to machinery malfunctions. In construction sites, they efficiently manage dust from activities like drilling and cutting, thereby improving air quality and reducing respiratory hazards for workers.

Some of the benefits of using industrial dust vacuums include:

- Enhanced workplace safety by reducing airborne dust and potential fire hazards.

- Improved air quality, contributing to healthier working conditions.

- Increased efficiency in cleaning operations, saving time and labor costs.

- Prolonged lifespan of machinery and equipment by preventing dust-related wear and tear.

These advantages underline the importance of investing in high-quality industrial dust vacuums that meet the specific needs of the business.

Choosing the Right Industrial Dust Vacuum

When selecting an industrial dust vacuum, several factors should be considered to ensure it meets the specific requirements of the environment. First, assess the type of dust or debris that needs to be managed. Different vacuums are tailored for various materials, from fine dust particles to larger debris like wood chips or metal shavings.

Another critical factor is the filtration system. Ensure that the vacuum has an efficient filtration mechanism capable of trapping the smallest particles. HEPA filters are highly recommended for environments where air quality is a top concern. Additionally, consider the power and capacity of the vacuum, as these will determine its effectiveness and efficiency in handling large cleaning tasks.

It’s also important to evaluate the durability and ease of maintenance of the vacuum. Industrial environments can be harsh, so a robust design that can withstand rough conditions is essential. Finally, consider the mobility and ease of use, especially if the vacuum needs to be transported across different areas frequently.

Conclusion: The Role of Industrial Dust Vacuums in Modern Industry

Industrial dust vacuums are a vital component of modern industrial operations. They not only enhance safety and health standards but also contribute to operational efficiency and equipment longevity. As industries continue to evolve, the demand for efficient and reliable cleaning solutions will only increase. Investing in a suitable industrial dust vacuum is a proactive step towards maintaining a clean, safe, and productive work environment. By understanding the various features and applications of these vacuums, businesses can make informed decisions that align with their operational needs and regulatory requirements.